The logistics of international trade can be defined by three key processes: the movement of goods or services, the measurement of this movement, and the processing of what is being moved. Each one of these processes face significant limiting factors when carried out on an international scale due to various geographical barriers (such as seas, mountains, and simply long distances). Therefore, the landscape of international trade as we understand it today has been shaped by the innovations in logistics that have helped us navigate and overcome these limiting factors. This article will look at the three fundamental innovations that have transformed logistics and international trade: containeristion, information processing technologies, and fibre optic cables.

1. Containerisation – the beginning of a revolution

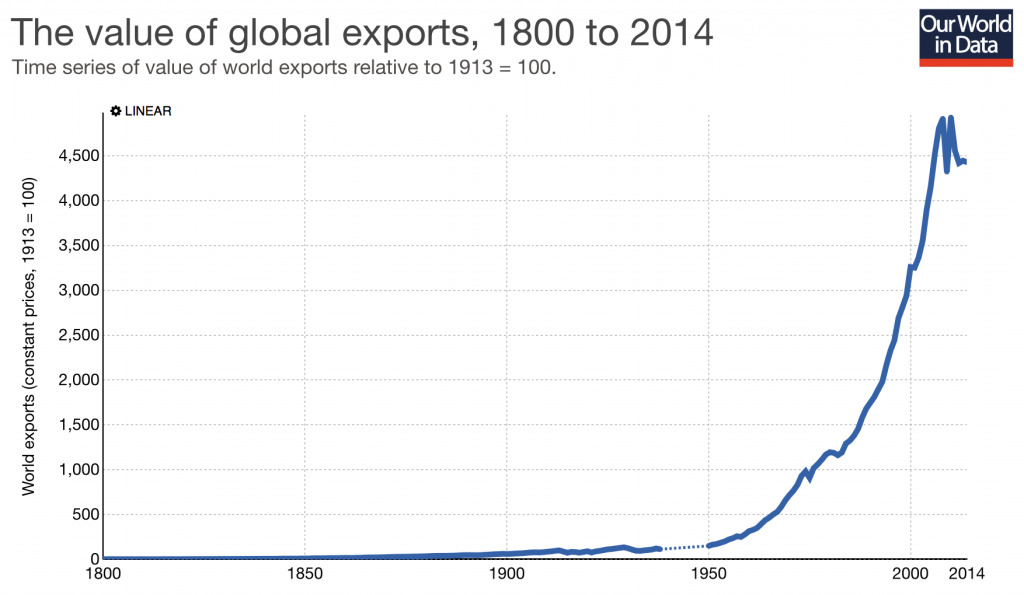

No innovation in business history is as important, yet simultaneously as undervalued, as containerisation. What was initially considered to be a minor innovation, containerisation turned out to be the single biggest driver of global imports and exports to date. When we look at the value of global exports (figure 1), we can see a direct link between the inaugural date of containerisation, 1956, and the explosion of global exporting activity.

Figure 1. Source: https://ourworldindata.org/international-trade

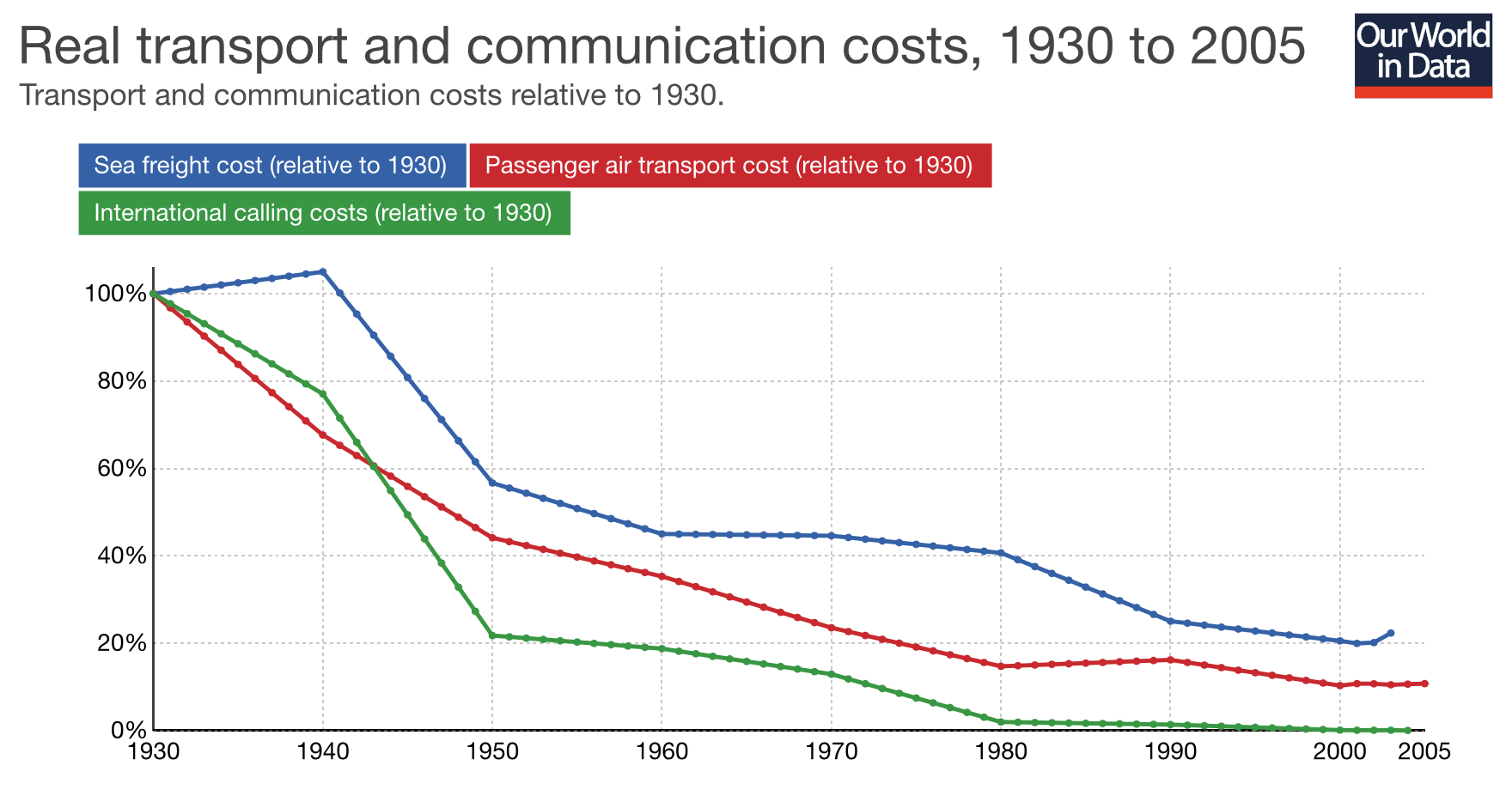

It is frequently argued that containerisation owes its significance in business history to its affect on reducing the cost of sea freight. Whilst it has certainly contributed to this reduced price (due to reducing labour and insurance costs), the key cost driver in shipping is the price of oil. When we look at the real cost of sea freight between 1960 and 1980 (figure 2) – the time period when containerisation made its most prominent advances – we can see that there was no significant change in sea freight cost. This is due to a 950% increase in oil price over the same period that acted to nullify the impact of any cost reductions made.

Figure 2. Source: https://ourworldindata.org/international-trade

Therefore, containerisation must be viewed as revolutionary not because of its impact on cost, but rather because of its impact on time. Prior to this innovation, ships would typically be in port for a couple of weeks due to loading and unloading being extremely time consuming. Now, however, a ship can be in and out of port within 10 hours. Whilst this increase in speed is beneficial for all types of products, perishable goods in particular were dramatically affected. Time is the key limiting factor in the long-distance transfer of perishable goods and without the speed increases brought about by containerisation, the fresh food industry would not have the international configuration it has today.

2. Information – Just In Time for disrupting the industry

For the next innovation, we turn our attention to the Japanese car industry and their Just-In-Time (JIT) manufacturing process. JIT production was a reconfiguration of the traditional manufacturing process that shifted the supply chain from being forecast-driven to demand-driven. Such a seismic shift was dependent on the innovations made in the information processing sector, in particular the barcode. The introduction of the barcode into the supply manufacturing process allowed for the faster and more reliable tracking of materials as they moved around a production circuit. Without this increase in efficiency, the dynamic flows that are required for a JIT system would not be attainable.

It is crucial to recognise that the importance of the barcode in the development of logistics is dependent on the computer systems capable of processing the data that the barcodes provided. The combination of computing power with the barcode allowed managers to have a better knowledge of what is where within their supply chains. This knowledge is necessary in order for a JIT system to function as small disruptions within the process can lead to long delays in production. Therefore, the combination of the innovation of the barcode, which allowed data to be easily and cheaply tagged to items, and the innovation of the computer, which allowed for the translation of this data into knowledge that could be utilised by the human operator, meant leaner international production systems could be developed.

3. Fibre Optic Cables – Hidden treasures of the sea

Born-globals are a recent phenomenon that can be defined as a business that operate on a global basis from the outset. The key limiting factor that prevented the possibility of born-global firms was the inability to quickly and cost-effectively communicate transnationally. If the rapid movement of information and ideas between geographically dispersed nodes of a business is not possible, then internationalisation of that business cannot occur. A business cannot exercise direct control in a host country if it cannot communicate with these foreign units.

The communication limiting factor was overcome by large corporations at an earlier stage due to economies of scale. It was not until the drastic reductions in overseas communication costs, shown in figure 2, that small emerging firms were able to overcome this obstacle. Although submarine cables had existed for over 100 years already, it was not until the fibre-optic cable that the movement of information was quick enough to be of use in an internationally dispersed business.

Looking to the future

It is vital to understand the role that innovations in logistics will play in the future transformation of international trade. One innovation that has great potential for reshaping current supply chains is the drone. If unencumbered by legal restrictions, the drone will be able to provide a low-cost, high-speed mode of transport. The significance of this technology can be seen by the interest that many of the major distribution companies have in it (Amazon, DHL, UPS etc.). For a complete analysis of trade and trade finance in the future, check out why 2017 will be a great year for trade finance.