A new report has found that the semiconductor, electronics, and pharmaceuticals sectors are leading the way in the digital transformation of manufacturing.

The Manufacturing Transformation Insights Report 2022, published yesterday by the World Economic Forum (WEF), offers new insights on how manufacturers large and small are focusing their efforts on connectivity and process integration.

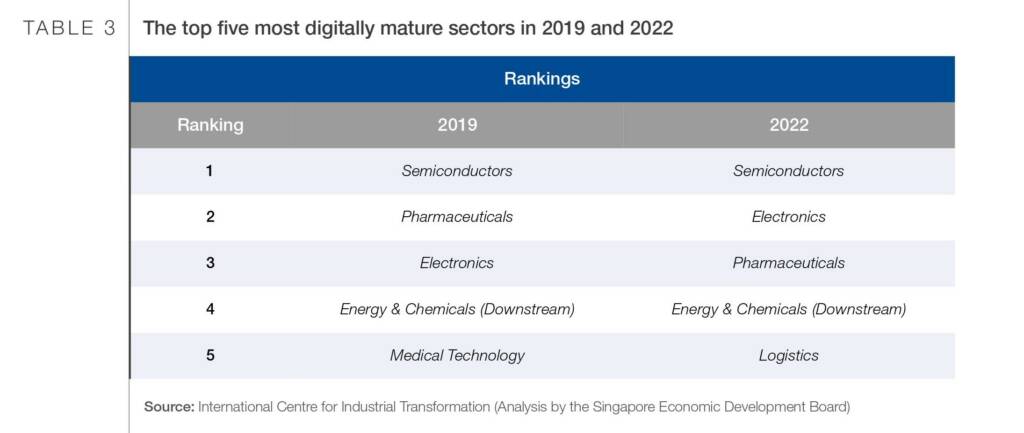

Based on a study of almost 600 manufacturers across 30 countries, the report ranked semis, electronics, and pharmaceuticals as number 1, 2, and 3 respectively in its digital maturity rankings.

As the authors note, this positioning is all the more impressive, given that these industries are not shielded from present-day challenges such as ongoing value-chain disruptions, the global chip shortage, and industrial decarbonisation.

Coming in at number 4 and 5 respectively was energy and chemicals (downstream) and logistics.

Digitalisation divergence

One of the key findings of the report was the divergence between small and medium-sized businesses (SMEs) and multinational corporations (MNCs) in terms of digital maturity.

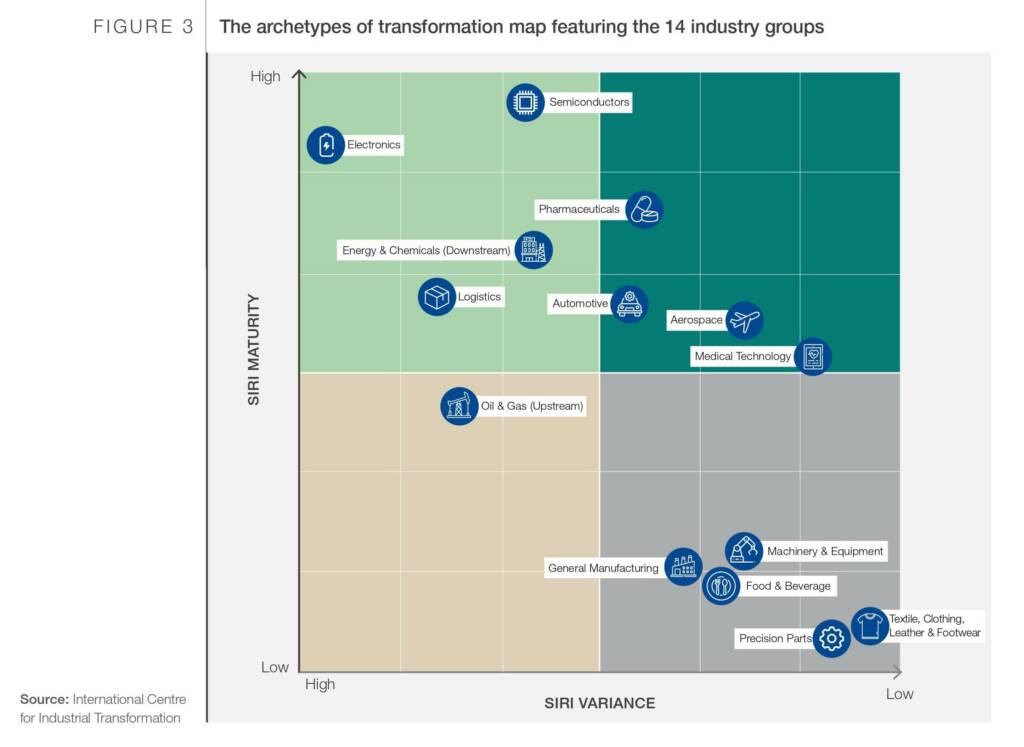

In general, SME-dominated sectors are less digitally mature than MNC-dominated sectors.

For example, the bottom five-ranked industries – namely precision parts; clothing and textiles; food and beverages; machinery and equipment; and general manufacturing – are all dominated by SMEs.

The report therefore calls for more tailored approaches to support industry transformation.

While governments and solutions providers tend to apply “one-size-fits-all” approaches in supporting manufacturers towards digitalisation, the impact and efficacy of such blanket interventions have been limited, the report found.

Such interventions include state-level subsidies for the adoption of new automation equipment, or industry-led forums that study use cases of global companies.

The inefficiency of these interventions can be seen in the fact that the most digitally mature companies are seeking to integrate their already-digitalised processes and systems, while the average manufacturer today is still looking to digitalise their operational processes.

The connectivity key

Another key insight from the report is that top companies have focused significantly on connectivity to enable greater integration and insight generation.

As such, many have already established interoperable and secure networks within their production sites, where equipment, machinery, and computer-based systems can interact and exchange information with few restrictions.

On a related note, the report calls for manufacturers to put more emphasis on refreshing and broadening their strategies for digitalisation and workforce retraining.

As manufacturers formalise their digitalisation strategies to upgrade their manufacturing and enterprise processes, there is also a need to re-examine the way they organise their workforce and workspaces as remote working becomes more prevalent in the digital era.

Report methodology

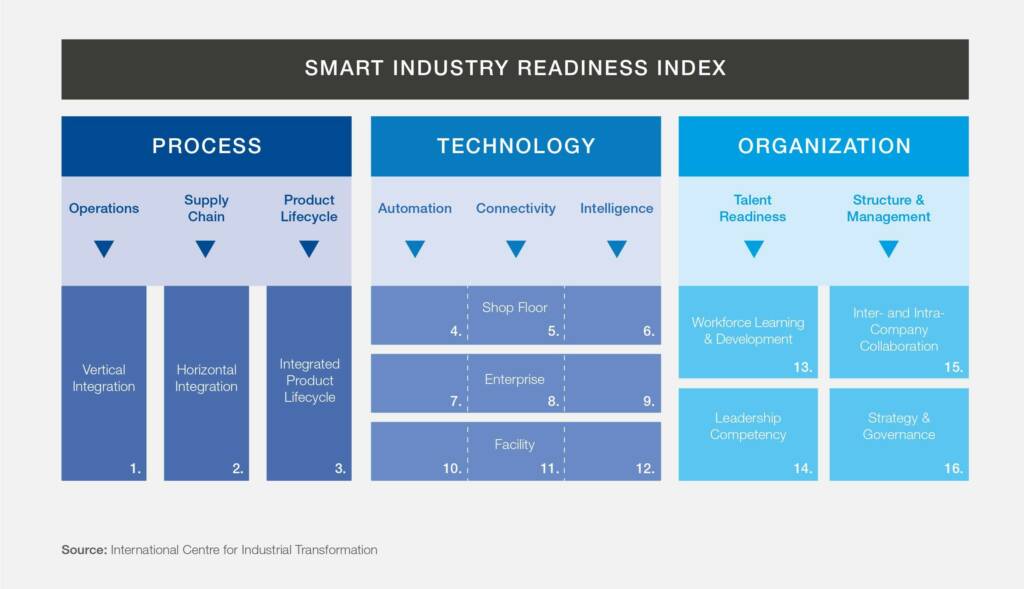

The report is based on the WEF’s Global Smart Industry Readiness Index (SIRI) Initiative, the first international programme to benchmark the current state of manufacturing globally.

In collaboration with Singapore Economic Development Board (EDB), the nearly 600 manufacturers studied all underwent the Official SIRI Assessment: a two-day independent review of a factory or plant.

Additionally, to support the international scale-up of SIRI, the WEF has also launched a new non-governmental, non-for-profit organisation.

The International Centre for Industrial Transformation (INCIT), as the NGO is known, will support SIRI in its goal to catalyse the adoption of Industry 4.0 methodologies and technologies in manufacturing, and provide quantitative indicators for international benchmarking.