Listen to this podcast on Spotify, Apple Podcasts, Podbean, Podtail, ListenNotes, TuneIn, PodChaser

Season 1, Episode 17

Host: Deepesh Patel, Editor, Trade Finance Global

Featuring: Imran Arshad, Founder of Eventuri

So, exporting is great but very hard, particularly for UK exporters today as the global economy is changing fast. Despite the global financial crisis and Brexit, UK exports are worth around two times more in 2017 than they were in 1997. When we consider the difficulties or grappling with tariff changes and certificates of origin terms, as well as all the customs documentation, that is no mean feat.

The UK exports vehicles and vehicle companions to more than 160 countries worldwide. Last year, one and a half million cars were manufactured for exports here. That is 81.5% of all vehicles produced in the UK. We spoke to the winner of the Queen’s Award for enterprise and international trade at the Institute of Export summer reception last month. I caught up with Imran Arshad, founder of Eventuri, an SME that designs and manufactures advanced carbon fibre intake systems used for performance cars, from 3D printing to laser scanning. We’re amazed by the technologies, opportunities and markets that the company is using and we wanted to find out more. Hi, Imran, thank you for joining us on Trade Finance Talks.

Deepesh: I’m Deepesh Patel, Editor at Trade Finance Global.

This podcast is going to be about racing cars. Just kidding, but it got your attention. I’ll come back to racing cars later. So, exporting is great but very hard, particularly for UK exporters today as the global economy is changing fast. Despite the global financial crisis and Brexit, UK exports are worth around two times more in 2017 than they were in 1997. When we consider the difficulties of grappling with tariff changes and certificates of origin terms, as well as all the customs documentation, that is no mean feat. The UK exports vehicles and vehicle companions to more than 160 countries worldwide. Last year, one and a half million cars were manufactured for exports here. That is 81.5% of all vehicles produced in the UK. On this occasion, we spoke to the winner of the Queen’s Award for enterprise and international trade at the Institute of Export summer reception last month.

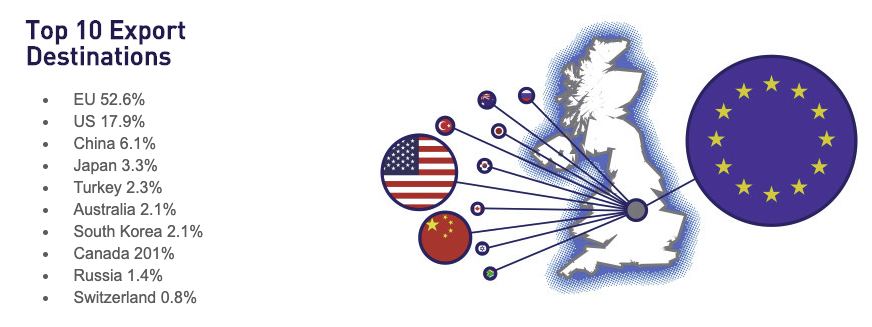

Key Exports Data

I caught up with Imran Arshad, founder of Eventuri, an SME that designs and manufactures advanced carbon fibre intake systems used for performance cars, from 3D printing to laser scanning. We’re amazed by the technologies, opportunities and markets that the company is using and we wanted to find out more. Hi, Imran, thank you for joining us on trade finance talks.

Imran: Hi, Deepesh, thanks for having me.

Deepesh: So, in no more than 30 seconds, tell us your elevator pitch. Who are you and what do you do at Eventuri?

Imran: My name is Imran Arshad and I’m the co-founder of Eventuri, along with two other brands that design, develop and distribute car modifications for the aftermarket. Eventuri designs boxes for performance cars, and we use cutting edge technologies such as 3D printing and scanning for prototyping. We distribute these products all over the world and, as Deepesh said, we did win the Queen’s Award for enterprise and international trade.

Deepesh: We met on a boat at the Institute of Export summer reception and you gave me a business card, which is probably what led to your being here! So, tell us a little bit more about this business card.

Imran: We got your attention! The business card is actually made from carbon fibre, which is what most of our products are made from. It does get the same reaction from everyone I give it to. I have given it to people and then a couple of years later I have met them in a different country and they’ve opened their wallet to show they still have the business card in there! They say they keep it because they show it to everyone they meet.

Deepesh: Excellent. So Eventuri was recently awarded the Queen’s Award for enterprise and international trade. Congratulations! What’s the secret to your success? Tell me a little bit more about your business and your journey as an SME exporter.

Imran: We started in 2014. Prior to that, my other business had been exporting to other countries, so we were able to utilise the existing distribution channels. Although we’re based in the UK, we only sell 10% if our product to the UK, while 90% of it is exported.

Deepesh: What components do you export?

Imran: We export the performance air boxes for performance cars. We literally redesign the air intake system that comes in combustion engine cars; every car that has a combustion engine has an airbox, which basically has two jobs. One is to provide that engine with air as part of the combustion process, and the other is to stifle the sound of it so the engine doesn’t sound too loud. We redesigned the box to give the car more performance and a bit more sound. It is mainly for performance cars like BMW because people who own those cars are generally interested in enhancing the performance of their car even further.

Export Opportunities for BMWs

Deepesh: Are Brits not buying BMW?

Imran: They actually buy a lot of BMWs, but what we find is that in the countries we’re exporting to, the end-user actually has a bit more disposable income. So, whereas here people are struggling to make the finance payments on the car, they don’t really appreciate the idea of paying good money for good quality, while people in other countries see it differently. Especially in places like America, where we find that people who have these types of cars tend to have more disposable income and are willing to pay money for quality products.

Deepesh: Very interesting. So, your production methods use very new technology such as 3D scanning, printing and CFD analysis. I was recently at ICC Beijing with Lionel Taylor and John Bujega and they were talking about how such cutting-edge technologies could really have an impact on supply chains globally, especially with regards to 3D printing. What are your thoughts on this? What opportunities can these methods create, particularly for your business?

We interviewed Lionel Taylor and John Bujega, on the impact of trade tariffs and 3D Printing on UK exporters – listen to the podcast here.

How It’s Made

Imran: I’ll just explain to what the technology design is, so you have an understanding of what we do. So, the main part of the process of us developing a product is the car comes in, and we 3D scan the engine bay, which then gives us the space that we need to be able to design the new product. That is then designed in a programme called Solid Works, which is a version of CAD. Once that’s designed, we can 3D print the prototypes. This saves us an amazing amount of time. Before, a product might take six months to design, but now we can have it all done in one week. We can also physically test that prototype on the car and verify that it’s working as it should do. Once that’s done, we can go to full production.

So, in terms of 3D printing and manufacturing, at the moment the main use of 3D printing is actually prototyping. But more and more people are using it for manufacturing. Just as an example, BMW actually 3D print the cylinder head for one of their latest engines.

So in terms, if manufacturing, it has huge implications because it could mean that, for example, let’s take frames for glasses. Rather than have them produced in China, someone can buy the design file and then print them on their printer. So they’ve literally cut out the whole process of that product being manufactured and then shipped halfway across the world. Not only does it save a lot of costs, but it also has implications for the environment, in terms of shipping. Then there is all the employment that is no longer necessary. It could really disrupt the way the world works.

Deepesh: That’s very interesting. Clearly, your company’s is making a huge difference to this industry. I want to go into a little bit more detail on your export journey. Tell me a little bit more about the barriers and the process, and also the opportunities that you see when you export to other markets, particularly some of your Asian markets.

Exporting Opportunities, Challenging and Tips

Imran: We started exporting to America first and then obviously Europe because they are a neighbour and it’s very easy to trade with these countries, especially America because it’s a large English-speaking nation. Once we got into those countries, we found that people from other markets started taking notice of our products. I think the main thing is actually going to see these people at trade fairs, seeing the people getting your product in their hands, so they can actually see the quality of it. We chose to use our brand on social media, mainly Instagram.

We take beautiful pictures of the products and make really cool videos. All of that’s good, but I don’t think there’s a substitute for getting a product into someone’s hands and meeting them personally. Part of my main role now is visiting our main distributors all over the world and maintaining the relationship we have with them. So as you know, as good as your product is, I do believe that the personal connection you have with the people that are buying is even more important.

Deepesh: So, trade fairs – are they primarily in the UK or overseas trade fairs? What I’d be very interested to find out is what the UK government is doing to bring you to trade fairs overseas?

Imran: At the moment, we’re not receiving any kind of funding. In terms of trade fairs, there is one in the UK, but we never go to it because the Tokyo Auto Salon in Japan is on at the same time – that region’s market is worth so much more to us than the UK so we skip it every year and go to Tokyo instead. Trade fairs are in almost every country – America has a really large one called Sema. That is in November and I believe it is the largest one in the world. I think it has 300,000 visitors and they are all trade customers rather than end-users.

Deepesh: Wow! In terms of the actual export journey, when it comes to exporting the parts from your UK warehouses, what is the journey and what are the challenges?

Imran: To be fair, we haven’t had any challenges really. The main challenge is finding someone in that country who can speak your language because obviously, we cannot speak Japanese. We find that a lot of the bigger companies in these countries do have an English-speaking person. So once that is sorted out, shipping the product out is not too much of an issue. Obviously, when the product gets to Japan, for example, they have their own Klay terrorists and customs officials that they have to deal with. But when you’re dealing with somebody who’s quite experienced, they understand that and they build that cost into the product. So when they retail the product in that country that’s already built-in. In terms of challenges, I think it’s actually getting your product to these people and then getting over the language barrier. Once you’ve done that, it becomes easier.

Deepesh: That’s very interesting because I think there’s a lot of perception in the industry that things like incoterms, custom declarations, tickets of origin, etc. and the cost of employing specialists can be prohibitive when exporting to Asia, for example.

Imran: We haven’t really seen a problem with that. Yes, you have forms to fill out, but we just see that as an extra bit of admin that we have to do. I think the only country we have had some problems with is South Korea because they have a trade agreement where if you have something from a different origin, such as England – and there’s no taxation – they’re very strict in how they apply that. We have ended up having to put ‘Made in England’ stickers on every component rather than just the box, which gets a bit difficult. But realistically, that’s the only problem I can tell you about. Because the expo black market is worth so much, it is a very small barrier to the enormous amount of failures out there.

Germany will negotiate to the “last hour” to avoid no-deal Brexit

Deepesh: Very interesting. I mean, I think that’s the reason why you guys won the Queen’s Enterprise. Let’s talk about Brexit and a no-deal Brexit – the automotive industry is probably one of the most at threat from trade tariffs, given the complexity of the UK supply chain. Is this impacting your business? Does this worry you? What’s your outlook on the sector?

Imran: Yeah, so it is a concern at the moment. It’s not impacting the business yet because we don’t know what’s going on. It did initially because it was affecting people’s ability to commit to spending money or commit to stock, but now it’s got to the point where people have given up trying to guess what is going to happen, so they’re carrying on as normal. In terms of the impact of a no-deal Brexit, it is something that our German distributors are particularly worried about because our product provides most of their revenue. They’re understandably concerned about a price hike in the product. Personally, I’m more concerned about actually getting the product there. Once there’s no-deal, if we can get the product there, I think our product can survive. Having a price hike in terms of the actual customs itself…I don’t think it’s going to be that much. I mean, when we import something from America, we play a couple of per cent. It is going to make a difference in terms of admin costs because we’ll have to fill out more forms, but it’s the uncertainty that is killing everything right now, rather than what is actually going to happen. I mean, Germany still has a lot of product coming from England and they also export a lot to England. So I’m sure they will come to some kind of agreement. But I think the sooner the better because the uncertainty is the worst thing about it.

Deepesh: That’s very interesting. We hear this so often, particularly from SMEs, but also right up to large companies with very complex supply chains – let’s make a decision because businesses can plan and prepare for whatever circumstances are there and try to mitigate the risks etc.

Imran: One thing I wanted to add was that if push comes to shove, and it becomes very difficult, we have already talked about making a base in Germany, where we can actually have a separate manufacturing plant. We would have the components sent out there and we manufacture there, but we will see what happens.

The Future of Exporting

Deepesh: It goes back to how businesses are thinking about different scenarios and preparing around the risks there. On to my penultimate question now – what advice would you give a founder or CEO who’s just starting their exporting journey?

Imran: I would say don’t be afraid of exporting, don’t think that there’s a barrier, that barrier is literally in your head. Get out there, go to trade fairs – even if you’re not exhibiting, because all the people you need to speak to are there, they’re all in one place. So regardless of whether you have a booth and you want people to come to see you but you can’t afford it…just go out there and arrange meetings with people. Show them your product and just do it really! It can be scary, but it is very important to meet these people in the flesh, show them your product and show them there’s a face behind it. For me, that’s been the most important part of the whole export journey we have had.

Deepesh: Thank you very much. So, for my final question – what are the medium- to longer-term objectives and strategy at Eventuri and what things are you focusing on? How do you think you’re going to be over the next few months?

Imran: With Eventuri, we were heavily reliant on having a combustion engine in the car, which obviously leads to the elephant in the room about electric vehicles. So, a couple of months ago, I started another brand, which is related to what we’re doing, but it’s actually to make aesthetic Aereo parts for cars, including electric vehicles. I’m hoping to launch that in November because I realised the lifespan might be maybe 15 to 20 years. This is me hedging my bets on other products and diversifying. For me, it’s about carrying on making new products because I am very aware of where the future is going. I am actually mitigating my business risk by creating a product that won’t be affected by all the electric vehicles that are coming in

Deepesh: Thank you very much Mr Arshad, that was fascinating. It was very interesting to hear your story about how you’ve grown the business by exhibiting at trade fairs and just going out there and speaking to people, despite the possibility of language being a barrier. There are clearly a lot of opportunities out there and your business is a great example of that – 10% of your business is being done in the UK and kudos to you and your entrepreneurial attitude, in terms of adapting to a changing market. It is interesting that you are looking at the way the industry and car market is changing and what it might look like in 10 to 15 years. It is good for our listeners and new exporters to hear this. It is a fantastic example of a company and an entrepreneur who is doing amazing things. So, thank you very much for joining us today, it has been really good to have you onboard and we’ll keep in touch.